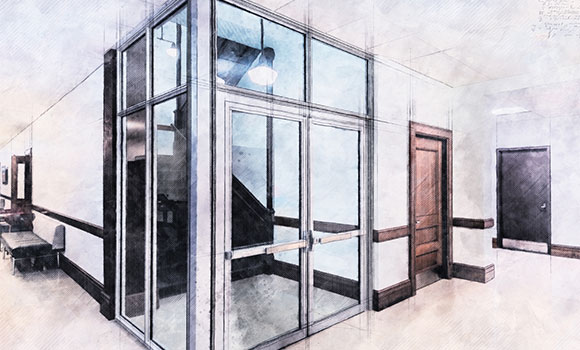

Fireframes® Designer Series die-rolled steel profile doors are full-lite, fire-rated doors with the appearance of narrow-profile aluminum storefront doors. A sleek alternative to typical hollow metal doors, Fireframes Designer Series doors feature precise edges, professional finish, and the narrowest sightlines available with a fire rating. Pre-hung, pre-finished and easy to install, Fireframes Designer Series doors complement adjacent non-fire-rated doors and can elevate the aesthetics of your project.

Fireframes Designer Series with monolithic glass and Fireframes Designer Series with Insulated Glass Units have both earned a Living Building Challenge Red List Approved Declare Label. These Declare labels can be used for building projects seeking to achieve either the Living Building Challenge or LEED green building rating systems.

|

|

|

|

|

|

|

||||||||||

|

| Rating | Max. Single Door Leaf Size | Max. Exposed Glass Size Per Piece |

| 20 Min. | 43" x 95-7/8" | 36" x 88-3/4" |

| 45 Min. | 43" x 95-7/8" | 36" x 88-3/4" |

| 60 Min. | 43" x 95-7/8" | 36" x 88-3/4" |

| 90 Min. | 43" x 95-7/8" | 36" x 56-1/2" (divided lite door) |

| Doors: Singles and AA | Rating | Max. Width | Max. Height |

| Max. Door Leaf Size | 60/90 min. | 48-3/16" | 107-7/8" |

| Max. Door Opening Single | 60/90 min. | 48-1/8" | 108" |

| Max. Door Opening Active-Active (AA Pair) | 60 min. | 96-1/4" | 108" |

| Max. Door Opening Active-Active (AA Pair) | 90 min. | 85-3/8” | 96” |

Note: Individual lite sizes cannot exceed max. sizes shown above. For double egress and specific assembly patterns, please reference Architectural Specification Manual at fireglass.com/detail-drawings

All hardware for Fireframes Designer Series doors is supplied by Technical Glass Products. Please contact Technical Glass regarding your individual hardware requirements.

Standard door hardware package may include:

Use our interactive Door Design Tool for more information on the advantages of working with Fireframes® Designer Series and Fireframes Heat Barrier Series fire-rated glass doors. Click the hotspots for insights into the features and benefits of TGP’s fire-rated glass door systems.

The time, in minutes or hours, that materials or assemblies can be expected to prevent flames and smoke from spreading.

As heat develops within the source area, pressure within the enclosed room begins to build relative to the pressure outside. Once the fire reaches equilibrium in the positive pressure zone, smoke, hot gases and flames are forced through any openings in the door or window assembly. Testing to the UL 10C standard more closely simulates real fire conditions.

Blocks radiant and conductive heat transfer from one side of the glass to the other. A required characteristic of glass used as a wall.

Classified and labeled by Underwriters Laboratories, Inc.® (UL), an independent product safety certification organization.

Immediately following a furnace test, heated glass is subjected to water from a fire hose. The cooling, impact and erosion created by the hose stream tests the integrity of the glass. In the U.S., the hose stream test is required for all fire ratings over 45 minutes (all fire ratings require it in Canada).

Available as a temperature rise door with Pilkington Pyrostop® fire-resistive-rated glass for 60-90 minute applications

Temperature rise doors provide a barrier to radiant and conductive heat transfer.

Available in stainless steel frame finish options for increased design flexibility.

Building codes clearly define hazardous locations where impact safety glass is required. Glass with this designation has been tested to meet impact safety requirements required for areas such as doors, sidelights, and areas close to the floor.

FireLite IGU is a fire-rated insulated glass ceramic unit that also complies with energy codes. It is designed for use in exterior applications where energy codes require an insulated product, or for interior applications with special needs such as sound reduction.

Withstands continuous temperatures to 1292° F for use in high efficiency heating appliances.

The ability of glass ceramic to withstand sudden heating, cooling, or both without cracking, shattering or exploding out of the frame.

The ability of the glass to stop various types of ammunition. Ratings are assigned in levels from 1 to 8, with a Level 8 rating being the highest (able to stop a 7.62mm rifle lead core full metal copper jacket, military ball).

The capacity of an element in a building structure to support a weight in addition to its own.

Listed and labeled by Intertek, an independent assurance, testing, inspection and certification organization.

Glazing designed to increase the amount of time required to gain entry. This additional time is intended to allow for the enactment of lock-down protocols and to allow for the arrival of emergency response teams. May be used in areas with high risk of prolonged attack or in critical areas such as vestibules. Forced entry resistant glazing should also resist penetration from hand-held or hand-thrown objects such as hammers, crowbars, bats, knives, bricks and rocks. (Source: NGA Glass Technical Paper FB71-21)

This product is both fire- and security-rated and is appropriate for educational facilities.

This product is smoke-rated and tested to UL 1784.